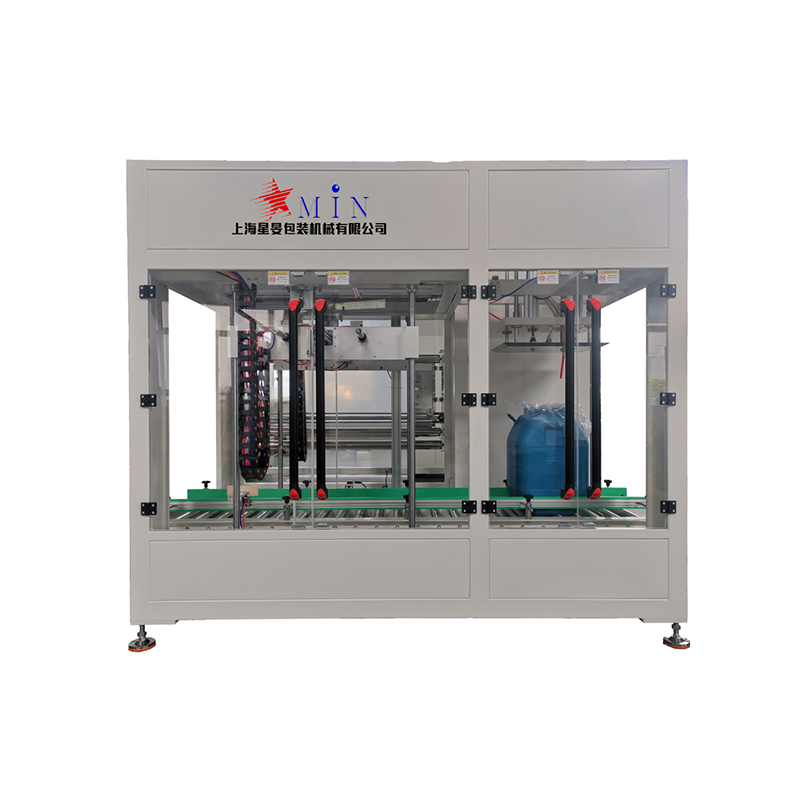

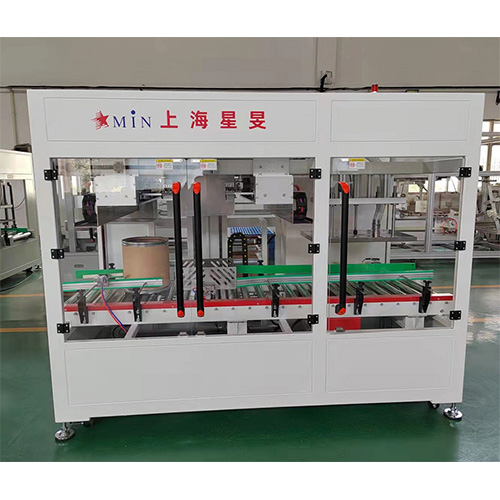

Viscous chemical product filling into bag and barreling packaging line

barrels insert into bag packaging line

May be you like

Equipment advantages

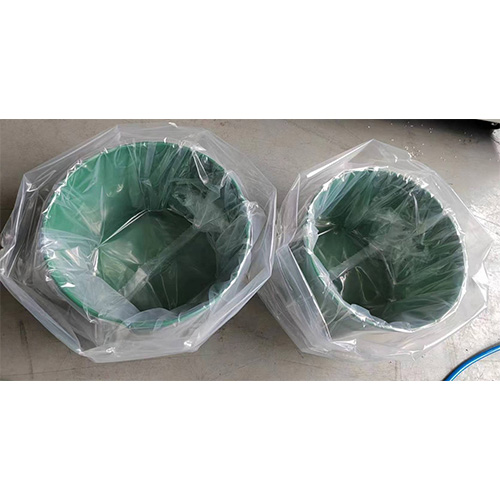

1. Plastic bags isolate air and water, protecting the product.

2. Convenient packaging and removal, keeping the barrel clean and pollution-free.

3. Machine bagging, smooth and efficient.

4. Labor savings.

5. This machine is ideal for bagging in environments where manual labor is not feasible.

6. Capable of bagging cartons, plastic boxes and barrels, metal boxes and barrels, and plastic bags.

7. Customizable packaging with special features, including explosion-proof and waterproof packaging, is possible.

Email: nopacker.nina@gmail.com

WhatsApp: +8618626223610

Leave us a message to share your needs. We will design a plan, provide on-site layout, design production equipment, and provide on-site installation and commissioning after sales service.

Key Components of a Barrel Packaging Line:

Barrel Loading & Washing: Systems for automatically loading empty barrels onto the line and washing them to prepare them for filling.

Bag inserter machine:bag inserter into the barrels for filling products into ,it's

Filling Machine: Utilizes flow meters or load cells for precise, high-volume filling of liquids or other materials into the barrels.

Capping/Sealing Machine: Automatically applies and seals caps or other closures onto the filled barrels.

Labeling Machine: Attaches labels to the barrels for product identification and information.

Case Packer: Packs the filled and sealed barrels into boxes for efficient handling and transportation.

Robot Palletizer: Stacks the cased barrels onto pallets to optimize space and prepare them for shipping.

Control System: An integrated PLC (Programmable Logic Controller) or SCADA (Supervisory Control and Data Acquisition) system manages the entire line's operations, ensuring seamless and accurate movement of barrels and products.

Applications and Benefits:

Product Versatility: Lines are designed for a wide range of products, including mineral water, industrial paints, lubricants, food products, and various chemicals.

High-Volume Production: The automation of an entire line significantly increases production efficiency and speed, meeting the demands of large-scale manufacturing.

Reduced Labor Costs: Automated processes reduce the need for manual intervention, leading to lower labor costs and improved worker safety.

Accuracy and Consistency: Precision filling and automated handling minimize errors and ensure consistent product quality.

Example Applications:

Gallon Water Production: Fully automatic lines for 5-gallon water bottles, integrating washing, filling, capping, and palletizing.

Industrial Liquid Packaging: Systems for filling and packaging drums, barrels, and IBCs (Intermediate Bulk Containers) with paints, solvents, and lubricants.